English

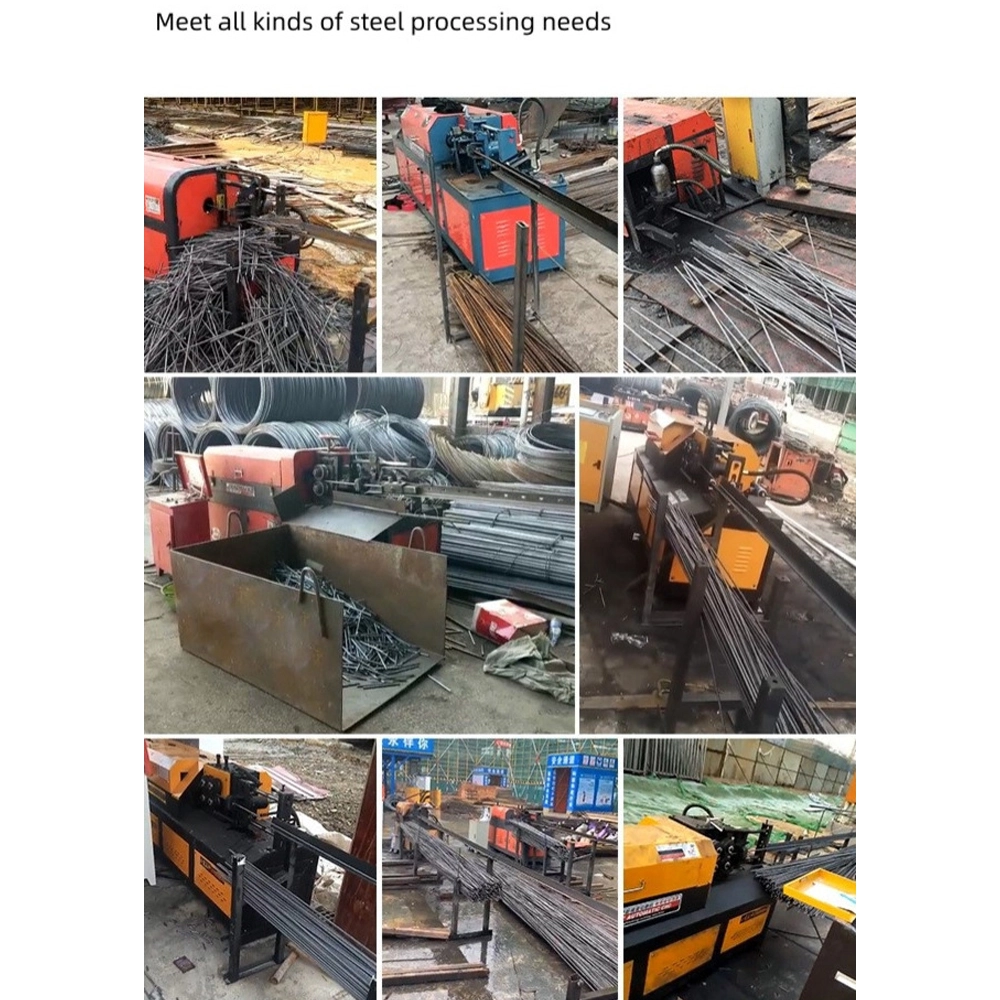

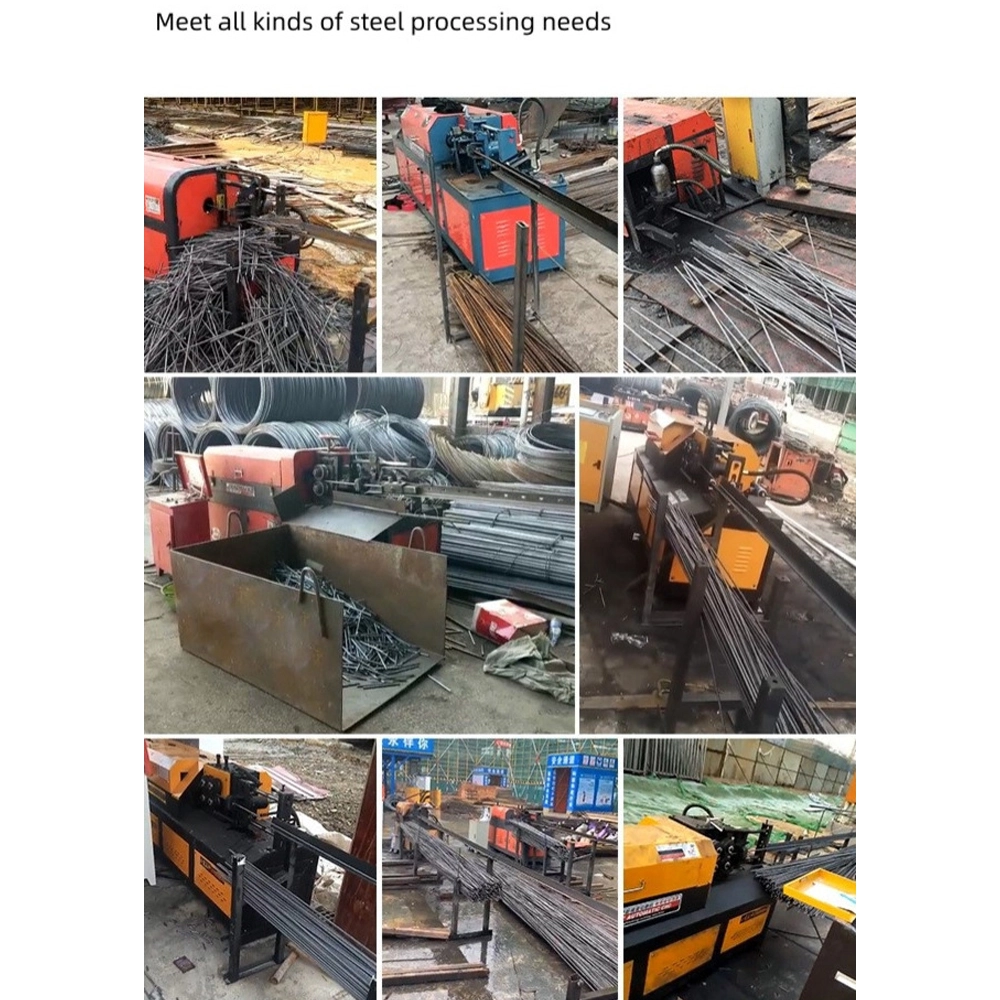

Minglei steel bar straightening and cutting machine is a specialized piece of equipment used in the construction and manufacturing industries to straighten and cut steel bars to desired lengths. This machine is essential for preparing steel bars for various construction applications, ensuring they meet the required specifications for structural integrity and ease of use.

The motor is heat-resistant and powerful.

High-temperature quenched forged gears are wear-resistant and durable.

Enlarged and deepened material trough can cut multiple steel bars at once.

Forged knife holder and connecting rod can withstand heavy loads for long periods without deformation.

Increased flywheel output makes steel bar cutting easier.

Dual control clutch lever is flexible and convenient.

Two types of blades available: round blade (for cutting round steel) and flat blade (for cutting threaded steel, hot-rolled round steel, square steel, carbon steel, and flat steel).

Wide range of applications: construction sites, tunnel construction, rebar processing centers, bridge construction, building material companies, and engineering projects.

Model | Motor speed | Power | Round steel | Rebar | Straitening speed |

MLR3-12 | 2860r/min | 3KW | 6-10mm | 6-8mm | 35-50m/min |

MLR4-12 | 2860r/min | 7.5KW | 6-12mm | 6-10mm | 35-50m/min |

MLR4-14 | 2860r/min | 9KW | 6-12mm | 6-10mm | 45-65m/min |

MLR5-12 | 2860r/min | 9KW | 6-12mm | 6-10mm | 35-50m/min |

MLR5-14 | 2860r/min | 11+5.5KW | 6-14mm | 6-12mm | 0-70m/min |

MLR6-14 | 2860r/min | 7.5+4.4KW | 6-14mm | 6-12mm | 45-65m/min |